MATRIX Technology

Wastewater Treatment Packages:

Wastewater treatment packages (WWTPs) were first introduced as a solution to the exporting and mobile regions of wastewater treatment industry to treat the municipal (or industrial) wastewater and procure irrigation water. The focus was to cover low-capacity, mobile, under developed regions where accessible trained operators and project management is a problem by prefabricating the whole plant in a transportable complete package. Therefore the nature of the project-based industry turned into the product focus in low-capacity segment.

These WWTPs are segmented in different aspects of (a) capacity, (b) tank material and (c) treatment process:

Capacity

Description

- Very small: Home & apartment sized for 1-50 person (1-10 m3/day)

- Small: Residential complexes for 50-500 person (10-100 m3/day)

- Medium: Big residential and commercial complexes, small towns, distributed WWTPs for 500-50000 person (100-10000 m3/day)

Tank material

Description

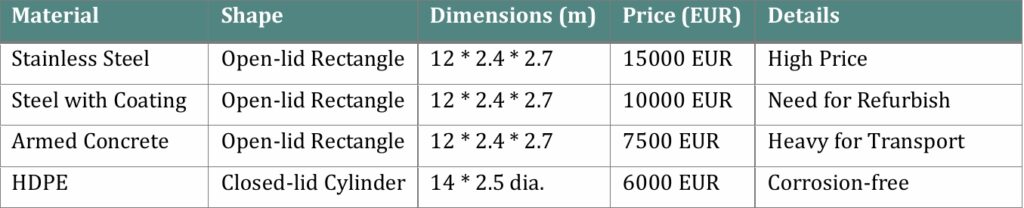

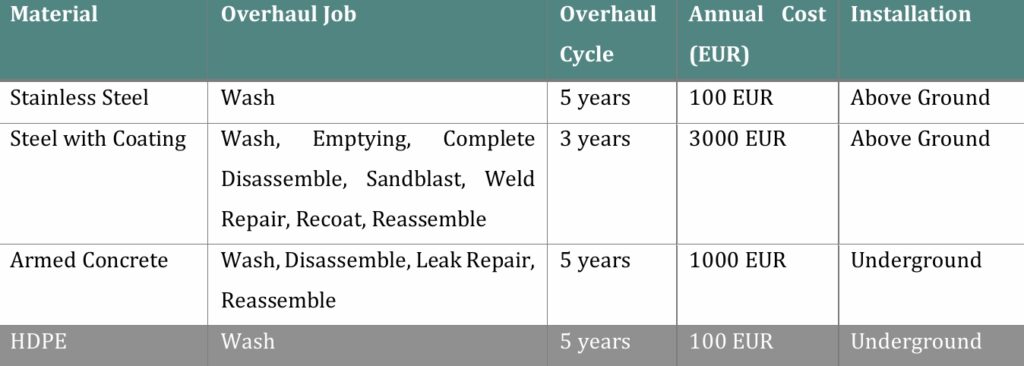

- Steel with coating (Zinc, Epoxy, …): It was the main material for exporting markets as the size and shape of the tank were tried to match a container size but the high rust and corrosion effect of the wastewater, reduced the coating and tank life and required complete coating refurbish. Mainly open-lid tanks.

- Stainless Steel: Rust-and-corrosion-durable material but very expensive. The design and dimensions are similar to steel with coating tanks.

- Prefabricated Armed Concrete: A mini typical on-site constructed wastewater treatment which could be designed closed-lid but the weight of the system is very high that limits the capacity.

- GRP Composite: Rust and corrosion durable but hard to build and seal.

- High Density Polyethylene (HDPE): Rust and corrosion free, closed-lid, completely buried (Underground Installation), light weight and relatively cheap material to build.

Treatment Process

Description

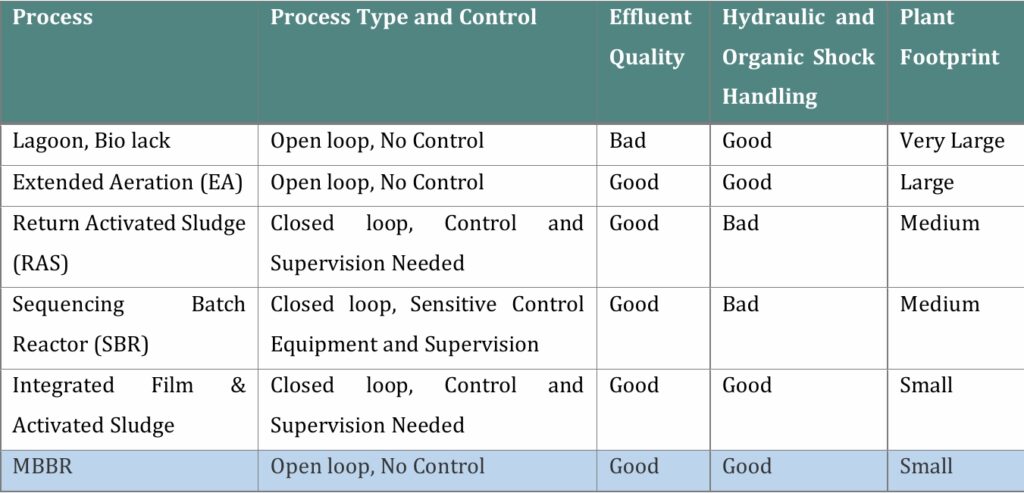

- Extended Aeration (EA)

- Return Activated Sludge (RAS)

- Batch Processes (SBR)

- Fixed Film (MBBR or IFAS)

WHY MUST YOU CHOOSE MATRIX?

The Right and Exact Solution, Competitive Price

Description

Combining the longtime industry of high diameter HDPE pipe production which has met the economy of scale as the main tank body (As the 80% of the tank price) with HDPE welding of walls, for different treatment zones sectioning (specific for every project and capacity and designed per project) and factory produced finished surface that requires no sandblast, coating, heat treatment, cleaning, gluing compared to other materials, which finally gives the most cost competitive system yet designed exactly per project. The following table shows the cost comparison of different materials for WWTP tanks (Similar volume of 70m3 with two separation walls):

Long-life, Durable Tanks, Easy Installation, No Maintenance

Description

As one of the most neutral materials, and excellent mechanical properties, the accepted life-span of HDPE in contact with wastewater is considered to be at least 50 years. MWWs use highly durable HDPE tanks and with easy underground installation, the tank could be guaranteed to the maximum.

No need to worry about corrosion, leak, break (could easily handle soil settlements) and coating refurbish. A simple wash and sludge collect at the bottom of the tank, will make it just like new.

The following table shows the rough estimation of annual costs of a 70m3, two walls tank:

Easy Process

Description

Process choice is the key to determine the plant footprint, shock handling ability, effluent quality and operation challenges. The following table shows the different wastewater processes:

Easy Underground Installation, Odor-free, Aesthetically Good, All-Weather Operation

Description

One of the challenges in small WWTPs is the low surface to volume ratio of the tanks compared to large wastewater treatment plants which tends to affect the treatment quality in case of temperature swings (Day-Night and Seasonal Cycles) and danger of surface frost in low-temperature winters that both lead to killing treatment bacteria and process restart, quality swings or odor emitting.

MWWs use underground, closed-lid design that in addition to solving seasonal temperature effects, the closed-lid design completely negates the odor and aesthetic problem and complains of the wastewater.

This design really shines in case of winds that either bring dirt and scum to the WWTPs or spread the emitted odor to the nearby regions. The closed-lid design solves all of the above and assures complain-free operation. In addition to the noted, the underground installation, in some cases, could omit the need for pump stations.

Easy Maintenance, No Process Shut-down

Description

MATRIX has dedicated a considerable amount of its R&D to design the systems and equipment to be durable, corrosion-free, light weight, accessible through manholes, could be easily extracted and serviced by a single operator and no need for process shut-down, tank emptying and going into the tank in time of service.

The result is a patented series of designs of equipment and careful selection of systems in order to meet the ultimate goal of “Easy Operation”.

Therefor there is no need for special service equipment and number of operators could be remained at the minimum.

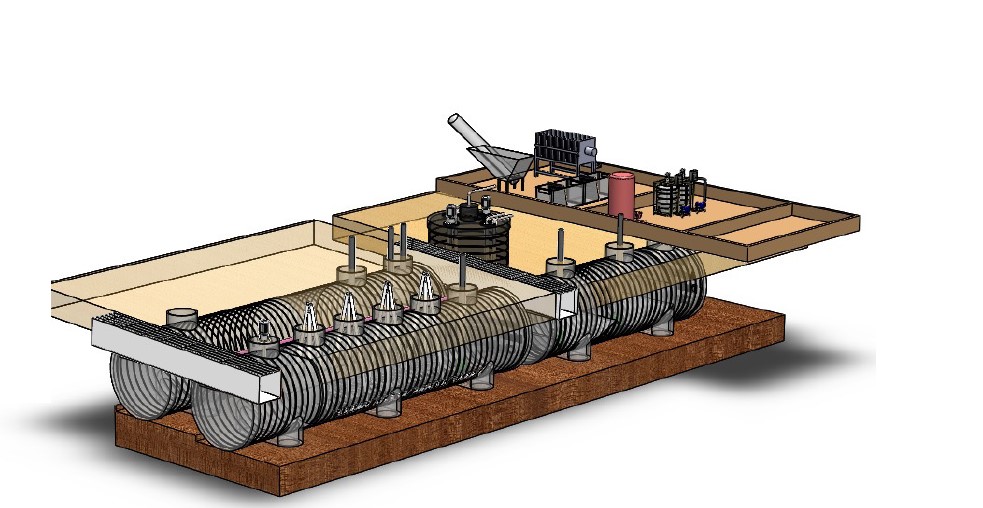

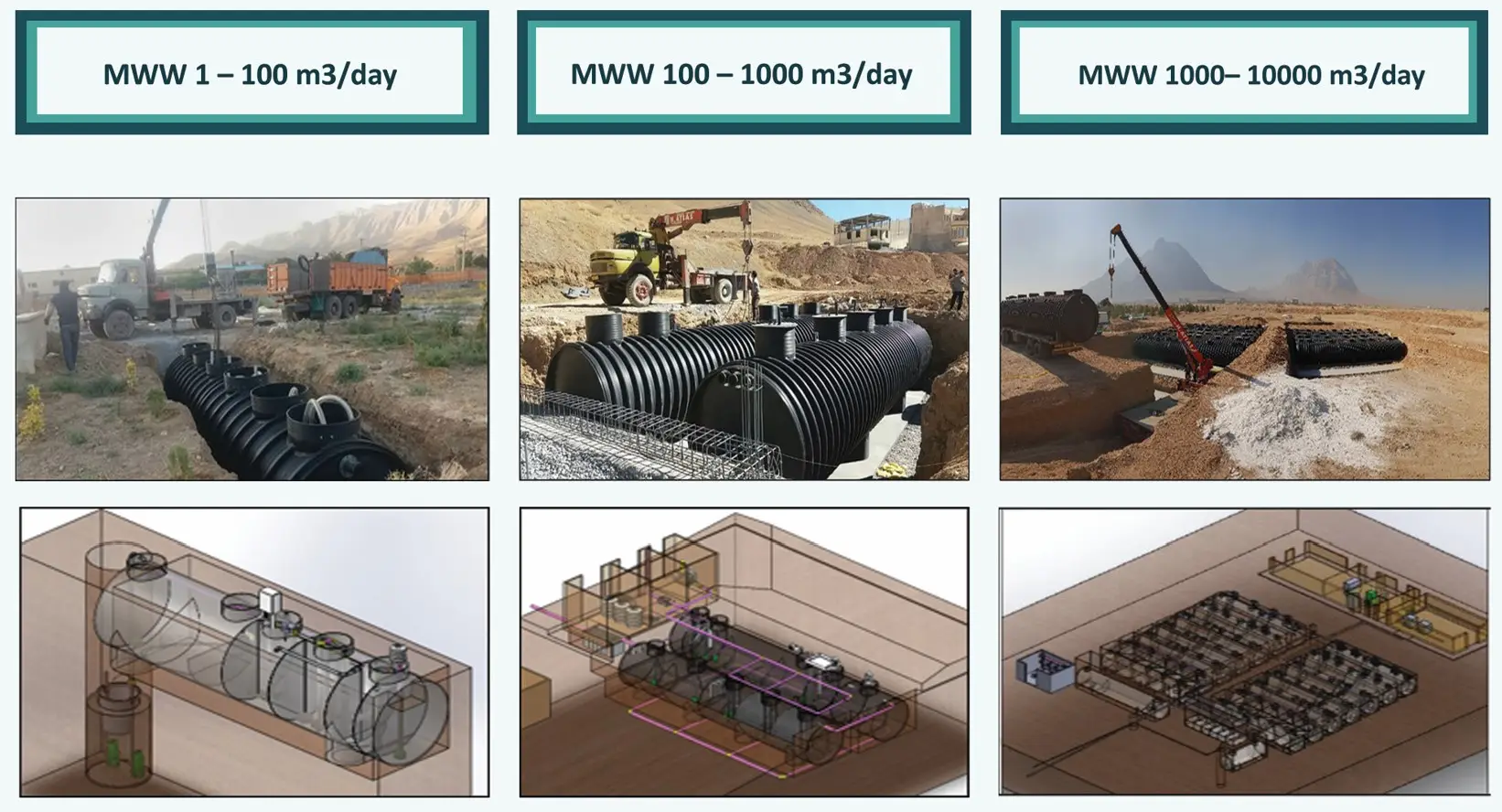

Modular Design, Covering Wide Range of Capacity

Description

The modular design allows the system to cover a wide range as following:

- 10-100 m3/day capacity in one tank design

- 100-1000 m3/day capacity in multiple tanks one or two module design

- 1000-10000 m3/day capacity in multiple modules design